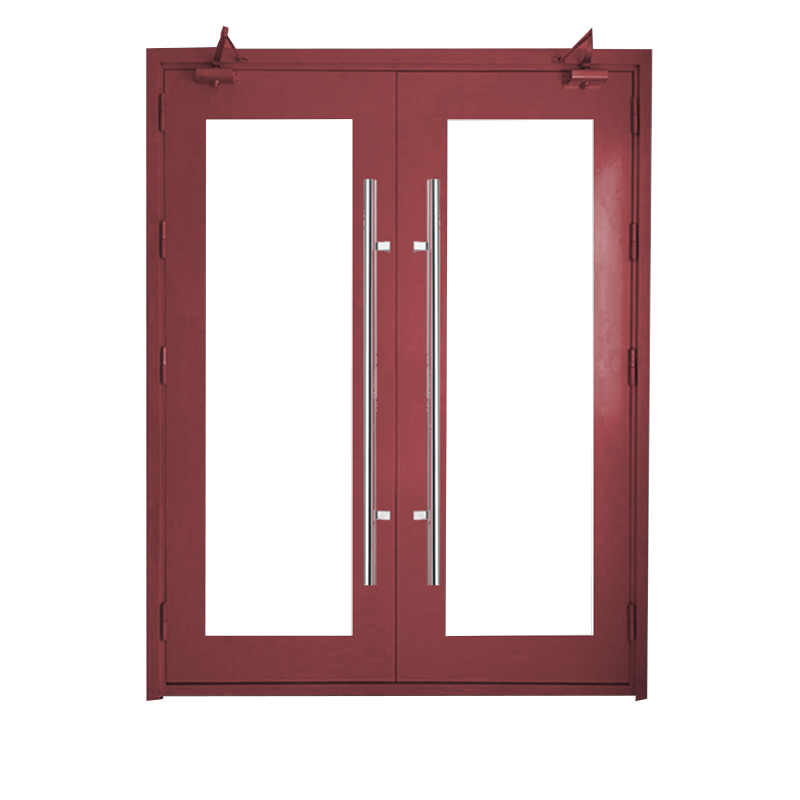

In scenarios where both fire safety requirements and ease of daily use are paramount,stainless steel glass fire doors,with their combination of tempered fire-resistant glass and a 304 stainless steel frame,have become an ideal choice that balances fire resistance with low maintenance costs.Their core advantage lies in achieving a balance between corrosion resistance,durability,and maintenance-free operation through material properties and process design.

Tempered Fire-Resistant Glass:Fire-Resistant and Transparent,Safe and Secure.Tempered fire-resistant glass is the core component of fire doors,employing a composite structure of”single-layer tempered glass+fire-resistant adhesive layer.”In the event of a fire,the fire-resistant adhesive layer expands upon heating,forming an insulation layer that effectively blocks the transmission of flames and high temperatures.Experimental data shows that tempered fire-resistant glass meeting national standards can maintain structural integrity for 1.5 hours,with the temperature on the unexposed side not exceeding 140℃,meeting the fire resistance limit requirements of Class A fire doors.Simultaneously,the tempering process gives the glass surface compressive stress exceeding 90MPa,making its impact resistance 3-5 times that of ordinary glass.Even if it breaks,it forms small,blunt-angled particles,reducing the risk of personal injury.In daily use,the smooth glass surface does not easily attract dust,and only periodic wiping with water is needed to maintain its light transmission.

304 Stainless Steel Frame:Corrosion-resistant,Durable,and Maintenance-free Design

304 stainless steel is the main material of the door frame.It contains≥18%chromium and≥8%nickel,and its surface naturally forms a dense oxide film,effectively resisting corrosion from humid environments and salt spray.Compared to carbon steel,304 stainless steel has more than three times the corrosion resistance,maintaining a clean surface even in coastal cities or high-humidity environments.The door frame design uses a”seamless process,”replacing traditional riveting with laser welding to reduce potential corrosion points;the brushed surface not only enhances the texture but also hides minor scratches,reducing the difficulty of daily cleaning.

Low-Maintenance Combination:Corrosion Resistance and Convenience in Synergy

The combination of these two elements,further optimized through process optimization,reduces maintenance burden:

Sealing:Fire-resistant silicone sealant is used between the door frame and glass,preventing smoke penetration and moisture intrusion,thus avoiding internal structural corrosion;

Hardware:304 stainless steel fire-resistant hinges and door closers are selected,with a nickel-plated surface to reduce friction wear and eliminate the need for frequent lubrication and maintenance;

Installation Standards:Appropriate expansion joints are provided during door installation to prevent deformation due to thermal expansion and contraction,extending service life.

From shopping mall passageways to hospital corridors,from data centers to industrial plants,the combination of tempered fire-resistant glass and 304 stainless steel frames provides modern buildings with an efficient and reliable fire protection solution characterized by”uncompromising fire safety and zero daily maintenance burden.”