In high-rise buildings,public facilities and residential areas,aluminum alloy fire doors are becoming a key barrier to ensure building safety with their light weight,high strength,corrosion resistance,fireproof and heat insulation.It not only meets the strict requirements of national fire protection regulations for fire protection performance,but also achieves the unity of beauty and function through modern technology,providing a multi-dimensional solution for building safety.

1.Structural and performance advantages of aluminum alloy fire doors

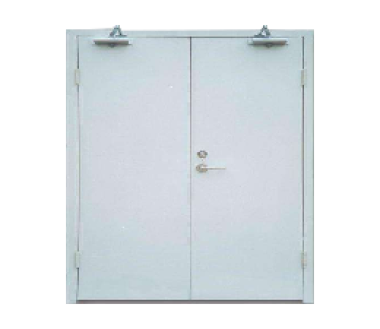

The core structure of aluminum alloy fire doors consists of door frames,door leaves and fireproof locks.The door frame is made of high-strength aluminum alloy profiles,and a stable frame structure is formed through precision extrusion technology;the door leaf is composed of aluminum alloy profiles and fireproof glass,and is filled with inorganic fireproof materials such as perlite and vermiculite to form a multi-level fireproof system.This design gives it three significant advantages:

Lightweight and high strength:The density of aluminum alloy is only 1/3 of that of steel,but it can achieve the same bending strength through profile section optimization,effectively reducing the load-bearing burden of the building.

Corrosion resistance:The surface anodizing treatment forms a dense oxide film,which can resist acid rain,salt spray and other harsh environments,and has a service life of more than 20 years.

Fireproof and heat insulation:The fire resistance limit of Class A aluminum alloy fire doors is up to 1.5 hours,and the thermal conductivity is as low as 0.3W/(m·K),which effectively blocks the spread of fire and heat transfer.

II.Application scenarios and performance matching

In high-rise buildings,aluminum alloy fire doors reduce the load requirements on building structures through their lightweight characteristics,while meeting the fire protection requirements of fire regulations for evacuation passages.Shopping malls,hospitals and other crowded places rely on their rapid escape function-Class A fire doors can maintain structural integrity for 1.5 hours in the event of a fire,buying precious time for personnel evacuation.Industrial plants use their corrosion resistance to deal with chemical erosion,and warehouses use fireproof glass to achieve visual monitoring of fire conditions.In residential areas,aluminum alloy fire doors not only improve the overall grade of the building,but also ensure the safety of residents through Class B fire protection performance.

3.Technological breakthroughs and material innovation

Modern aluminum alloy fire doors have achieved dual upgrades in materials and processes:

Thermal insulation strip technology:Nylon 66 thermal insulation strips are used to replace traditional PVC materials,reducing thermal conductivity by 40%and significantly improving thermal insulation performance.

Fireproof glass innovation:Laminated composite fireproof glass is compounded with multiple layers of glass and fireproof film to maintain structural integrity at high temperatures;hollow fireproof glass improves thermal insulation effect through an inert gas filling layer.

Surface treatment process:Fluorocarbon spraying technology forms a 0.5mm thick fluorocarbon resin coating on the surface of the door body,which increases weather resistance by 5 times and can resist environmental erosion such as ultraviolet rays and acid rain.

4.Key points for purchase and installation

Three core indicators need to be paid attention to when purchasing aluminum alloy fireproof doors:

Certification qualification:It is necessary to hold a type inspection report issued by the National Fireproof Building Materials Quality Supervision and Inspection Center,clearly marking the fire resistance level and scope of application.

Material testing:the wall thickness of the profile must be≥1.2mm,the light transmittance of the fireproof glass must be≥75%,and the melting temperature of the hardware accessories must be≥950℃.

Sealing performance:the gap between the door leaf and the door frame must be≤3mm,and EPDM rubber strips must be used to achieve airtight and watertight double sealing.

During the installation process,it is necessary to ensure that:

The door frame and the wall are connected with expansion bolts,and the spacing is≤400mm;

The opening force of the door leaf is≤80N,and there is no rebound after closing;

Normal closed fire doors must be equipped with automatic door closers,and normally open doors must be equipped with electromagnetic release devices.

V.Maintenance and maintenance strategies

Daily maintenance must follow the”three checks and three clears”principle:

Check hardware:check the flexibility of locks and hinges every month,and replace rusted parts;

Check sealing:check the aging of rubber strips every quarter,and repair cracks in time;

Check fire protection:conduct fire protection performance spot checks every year to ensure that the filling material does not fall off.

Notes for cleaning and maintenance:

Use neutral detergent to wipe the surface,avoid using strong acids and alkalis;

Wipe the water accumulated in the door in time after rain to prevent damage to the oxide film;

Regularly lubricate the door shaft and door closer to keep the opening and closing smooth.

Sixth,future development trend

With the improvement of building safety standards,aluminum alloy fire doors are evolving towards intelligence and modularization.Future products may integrate:

Temperature sensing system:real-time monitoring of door body temperature,automatic alarm when abnormal;

Remote monitoring function:remote viewing of door body status through Internet of Things technology;

Emergency escape indication:built-in LED light strip,automatically guide evacuation direction in case of fire.

At the same time,the application of environmentally friendly fireproof materials will further reduce the carbon footprint of products,such as the use of recycled aluminum alloy profiles and bio-based fireproof filling materials to meet the requirements of green building certification.

As the core component of the building safety system,the performance of aluminum alloy fire doors is directly related to the safety of life and property.Through scientific selection,standardized installation and regular maintenance,it can ensure that it plays a key role in emergency situations such as fire,providing reliable safety protection for modern buildings.With the iteration of technology,this field will continue to promote the deep integration of building safety and aesthetic design.